PQE Power System Sdn Bhd

C-10-01, Oasis Square,

Jalan PJU 1A/7A,

Ara Damansara,

47301 Petaling Jaya,

Selangor, Malaysia.

- Power Quality Solutions

- Power Quality Measurement Solutions

- Condition Base Monitoring Solutions

- Energy Efficiency Solutions

DTM Transformer Monitor

| Previous | 9 / 20 | Next |

The DTM Bushing Health Monitor detects problems to prevent failure of transformer bushings, windings, and the bus connected to the transformer.

The DTM Monitor configuration, historical data and detailed diagnostics provides an indication of the location, type and rate at which a problem is developing so that you can plan accordingly.

Continuous online monitoring of bushings provides real-time information of bushing capacitance and power factor which can result in the early detection of a possible failure. DTM may be ordered with up to two optional bushing (B) modules.

The bushing module collects top oil temperature, load current and humidity inputs to provide a correlation with the bushing condition. This allows the system to reveal whether there is a specific inception point where the equipment deterioration accelerates.

The bushing module provides a discrete reading for each bushing. The reference is rotated to each of the three bushings providing the same high quality of reading on each bushing.

The partial discharge module measures electrical partial discharges (PD) in the transformer, bushing, and when applicable, the connected Iso-Phase Bus. The DTM may be ordered with up to two optional (E) modules.

Electrical PD monitoring is the perfect second level diagnostic tool to complement DGA and bushing monitoring systems. While a DGA system can indicate the type of fault, the electrical PD system can identify electrically where a fault is in the tank (identifying the phase and the winding).

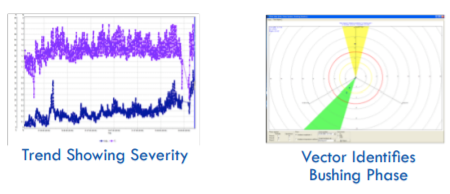

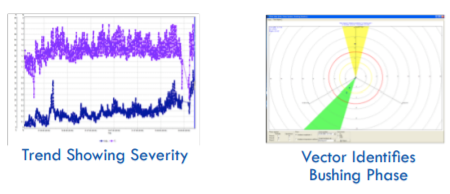

The key analytic for bushing monitoring is the magnitude and trend of the current imbalance. A DTM can provide system alarms on both of these quantities. Secondary analytics include behavior of the current imbalance with top oil temperature and the vector of the current imbalance. The magnitude of the current imbalance will provide information as to how severe the problem is. The vector will provide the indication of which bushing is failing and will identify if the power factor or capacitance of the bushing is changing.

The DTM Monitor configuration, historical data and detailed diagnostics provides an indication of the location, type and rate at which a problem is developing so that you can plan accordingly.

- Bushing Health Monitor Module (BHM)

Continuous online monitoring of bushings provides real-time information of bushing capacitance and power factor which can result in the early detection of a possible failure. DTM may be ordered with up to two optional bushing (B) modules.

The bushing module collects top oil temperature, load current and humidity inputs to provide a correlation with the bushing condition. This allows the system to reveal whether there is a specific inception point where the equipment deterioration accelerates.

The bushing module provides a discrete reading for each bushing. The reference is rotated to each of the three bushings providing the same high quality of reading on each bushing.

- Partial Discharge Monitor Module

The partial discharge module measures electrical partial discharges (PD) in the transformer, bushing, and when applicable, the connected Iso-Phase Bus. The DTM may be ordered with up to two optional (E) modules.

Electrical PD monitoring is the perfect second level diagnostic tool to complement DGA and bushing monitoring systems. While a DGA system can indicate the type of fault, the electrical PD system can identify electrically where a fault is in the tank (identifying the phase and the winding).

- Advanced Analytics

The key analytic for bushing monitoring is the magnitude and trend of the current imbalance. A DTM can provide system alarms on both of these quantities. Secondary analytics include behavior of the current imbalance with top oil temperature and the vector of the current imbalance. The magnitude of the current imbalance will provide information as to how severe the problem is. The vector will provide the indication of which bushing is failing and will identify if the power factor or capacitance of the bushing is changing.